At Riteweld Engineering, we specialise in turning architectural drawings into steelwork—transforming your vision from page to project with precision, safety, and expertise. Whether you’re an architect, project manager, or private client, our process bridges the gap between creative design and solid steel fabrication.

We work with clients across Oxfordshire, Warwickshire, Northamptonshire, and Gloucestershire, bringing concepts to life through expert planning, modern fabrication methods, and clear communication.

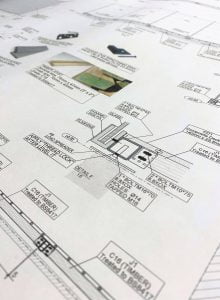

From Architectural Drawings to Steelwork – Our Process

We take a structured approach to turning drawings into reality, ensuring each step is quality controlled and aligned with client goals.

Step 1: Review and Consultation

We start by reviewing your architectural drawings, CAD files, or sketches. We work with architects, developers, and private clients to understand the full scope, constraints, and intent of the design.

Our team often supports early-stage design feedback and can collaborate with you and your structural engineer to ensure feasibility.

Step 2: 3D Visualisation and Planning

Before fabrication begins, we use 3D visualisation to preview the structure in full detail. This allows for quicker decision-making, early error detection, and design clarity.

🔗 Learn more about 3D design tools from the Royal Institute of British Architects (RIBA).

Step 3: Precision Steel Fabrication

With drawings confirmed, fabrication begins. We cut, bend, and weld all components in-house using state-of-the-art machinery. All work is fabricated to UKCA marking standards and aligned with building regulation requirements.

Services used during fabrication may include:

-

Plasma cutting for intricate shapes

-

Metal bending using press brake machinery

-

Custom finishing: galvanised, powder-coated, or painted

Step 4: Site Delivery and Installation

We manage the full supply and install process. Whether it’s balustrades, steel staircases, or supporting frames, we ensure each component arrives site-ready and is installed efficiently and safely.

Why Choose Riteweld for Architectural Steelwork?

✔ Based near Banbury – local to Oxfordshire

✔ We collaborate with architects and builders across Warwickshire, Northamptonshire, and Gloucestershire

✔ In-house 3D visualisation and CAD capability

✔ Specialists in architectural and structural steelwork

✔ End-to-end support: from design review to installation

Ready to Turn Architectural Drawings into Steelwork?

Whether you’re planning a staircase, balcony, or full structural frame, we’re here to help you turn your drawings into reality. Contact us for a free quote or to discuss your plans.

📞 Visit www.riteweldengineering.co.uk or call to speak with our team today.